Our Activities

5S Activities

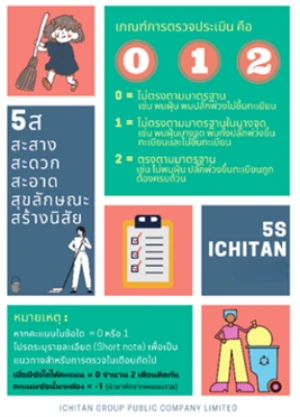

The activities have been organized continuously for 12 years as a foundation for creating work, creating habits, and promoting habits to work efficiently and safely in order to have positive impact on the operations within the organization, leading to a more efficient production process. The focus is on increasing work space, reducing equipment storage space, increasing work convenience and speed, and reducing accidents and risks at work for employees with the aim to create a good working environment. A 5S activity committee has been appointed and assigned to take responsibilities for assessing 5S activities, summarizing the assessment results, and monthly reporting to the 5S activity committee. The objectives are to promote continuous and efficient operations of the factory, and develop a quality standard system that is in line with the company's policies.